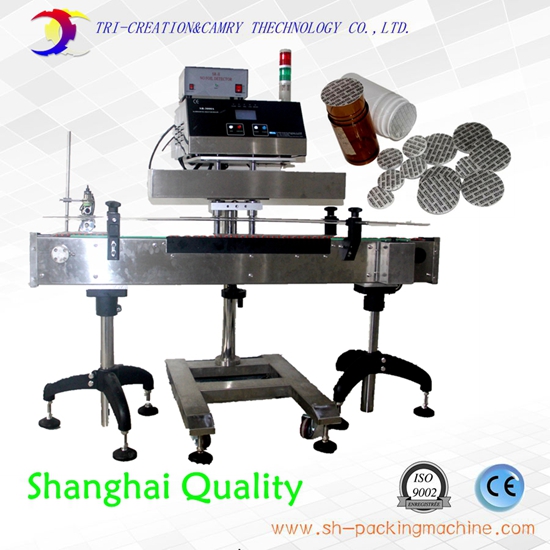

1)10 years experience of manufucture

2)No foil reject and alarm

3)20-80mm, 2500W

4)modulaer component design

5)CE

Application

Product: for pesticide, tablet & capsule, foods, cosmetic, lubricant &oil packaging etc. Plastic bottle and glass bottle sealing.

Product Features

1,Full modular component design, can be against moisture, erosion, dust and magnetism, minimizes maintenance requirements and increase the rease.

2,The induction generator has adopt the latest imported transistor and CPU module control

3,All functions are marked on the panel clearly . operation is very convenience

4,The induction sensor with 6 pieces 180°Ccopper coil and 5 pieces 220V fan( coil quantities can be chance accorder to bottle nect diameter), it can sealing quickly and perfectly.

5,Full Air-cooling systems, efficient high-speed, it can continual work for whole day

6,With stainless steel body, meet the GMP demand.

7,With the special alarm system, the machine will alarm when the tank water less, water temperature high

8, Host, stand, sensor head can be split to reduce transportation costs

The induction generator, shelf and induction seasor can be split to pack.This way can save the shipment cost

9,Height of induction sensor is adjustable and flexible for a range of bottle height.

10,The induction sensor and generator of same machine model can be change.

Our machine has get the CE authentication

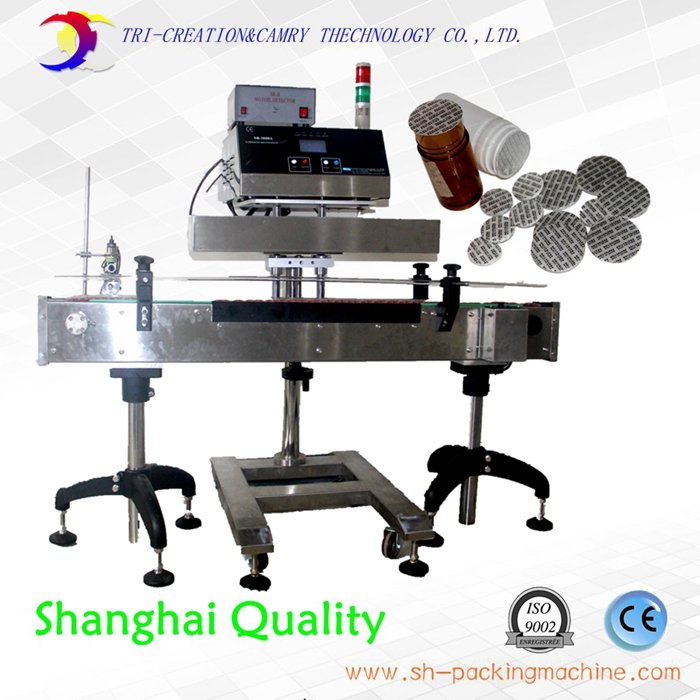

Technical parameters:

|

model

|

ZD-2500A

|

|

bottle neck diameter

|

20mm-80mm

|

|

bottle height

|

0-490mm

|

|

flow packing line speed

|

0-15m/min

|

|

max power

|

2000W

|

|

sealing speed

|

0-250blts/min

|

|

electricity power

|

380V 50Hz

|

|

induction sensor size(L*W*H)

|

665mm*170mm*100mm

|

|

Induction generator size

|

410mm*390mm*160mm

|

|

Shelf size

|

770mm* 640mm *105mm

|

|

machine weight

|

65Kg

|

|

packaged size

|

580mm*530mm*320mm

|

|

package weight

|

85kg

|