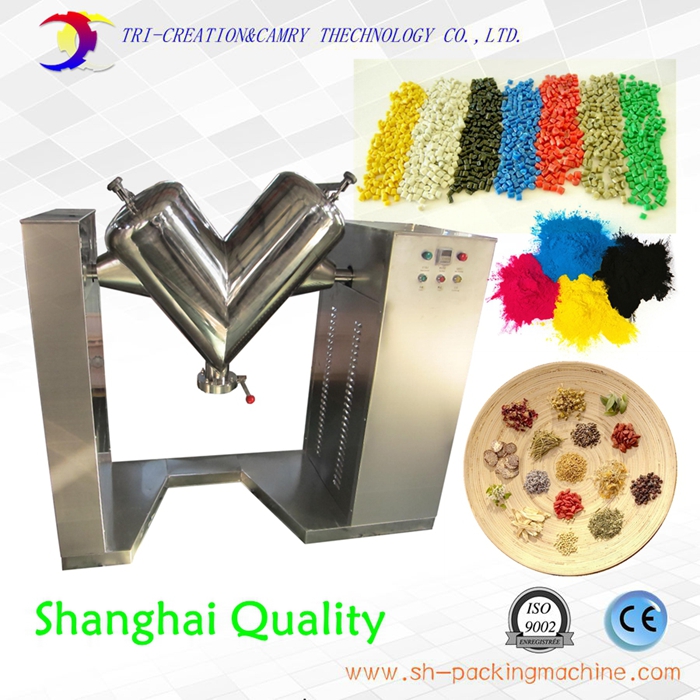

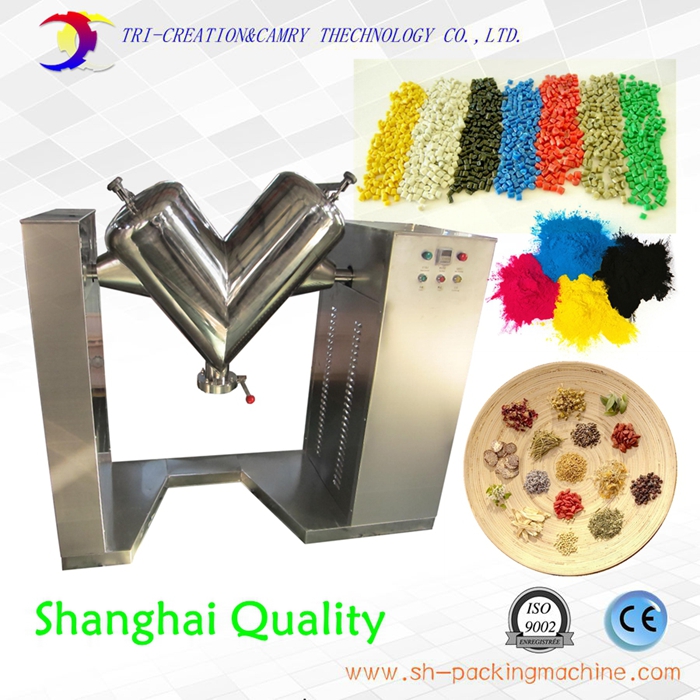

Product description:

The reducing mechanism drives the barrel rotary, and the length of two barrels is different,

which will produce asymmetry. And then the machine take advantage of this asymmetry

for mixing materials. When the machine is running, materials from the decomposition

to the combination, as potential energy differences, which will produce lateral force

to promote the horizontal exchange of materials; and materials from the combination

to the decomposition, as materials plane differences, which will produce lateral force

to promote the horizontal exchange of materials again. The barrels rotary one cycle,

which will make 25% of materials flow from one barrel to the other one; at the same time

the materials will also produce radial flow, and then the materials can horizontally

and radially decompose, alternating combination, so that the materials can mix evenly.

Product Features:

This machine adopts labor feeding and enclosed flapper valve for discharging.

It will not produce powder dust, and it also will not produce mechanical compression

and strong friction during mixing. So the material particles can remain intact.

The mixing barrel is made of stainless steel, which won’t pollute the material.

Besides, this machine has timing device, which can control the mixing time of materials.

Technical Parameters:

|

Model

|

VH-100

|

|

Volume

|

100L

|

|

Best charging quantity

|

30L

|

|

Max.charging quantity

|

40L

|

|

Dia. Of barrel

|

φ350mm

|

|

Dia. Of feeding port

|

φ160mm

|

|

Dia. Of discharging port

|

φ100mm

|

|

Rotary speed of barrel

|

15r/min

|

|

Power

|

1.1Kw

|

|

Outline dim.

|

1580×650×1460mm

|